Today’s Manufacturing Challenges

There are many challenges facing UK manufacturers today, including:

- Brexit: The UK’s decision to leave the European Union has created uncertainty and disruption for UK manufacturers, particularly those that rely on exports to EU countries.

- Supply chain disruption: The COVID-19 pandemic has disrupted global supply chains, causing shortages of raw materials, parts, and components. This has made it difficult for UK manufacturers to maintain their production schedules and meet customer demand.

- Competition: UK manufacturers face intense competition from low-cost producers in emerging markets such as China and India, as well as from manufacturers in other developed countries.

- Technology adoption (Industry 4): UK manufacturers must keep up with the latest technologies and innovation to remain competitive. This requires investment in research and development, as well as upskilling of the workforce.

- Environmental regulations: UK manufacturers must comply with increasingly stringent environmental regulations, which can be costly and time-consuming.

- Access to finance: UK manufacturers may struggle to access the finance they need to invest in new technologies, expand production capacity, and enter new markets.

- Skills shortage: UK manufacturers are facing a shortage of skilled workers, particularly in areas such as engineering, science, and technology. This can make it difficult to innovate and grow the business.

Industry 4 opportunities

- Those experiencing growth need to double / increase productivity .

- One of the best ways to achieve this will be through smart connected factories

- How do we reduce lead time and waste

- A connected supply chain can help here

- Halve the time to market ( if not achieve even faster times that this ( I have some major manufacturing companies present on the need to reduce from 100 weeks ( 2 years) to 300 days ) by exploiting data and digital twin

- Deliver customisation by enabling flexible operations

- Double labour productivity through integrated intelligent automation

- Creating increase value through disruptive new business models

The need for manufacturers to do things differently

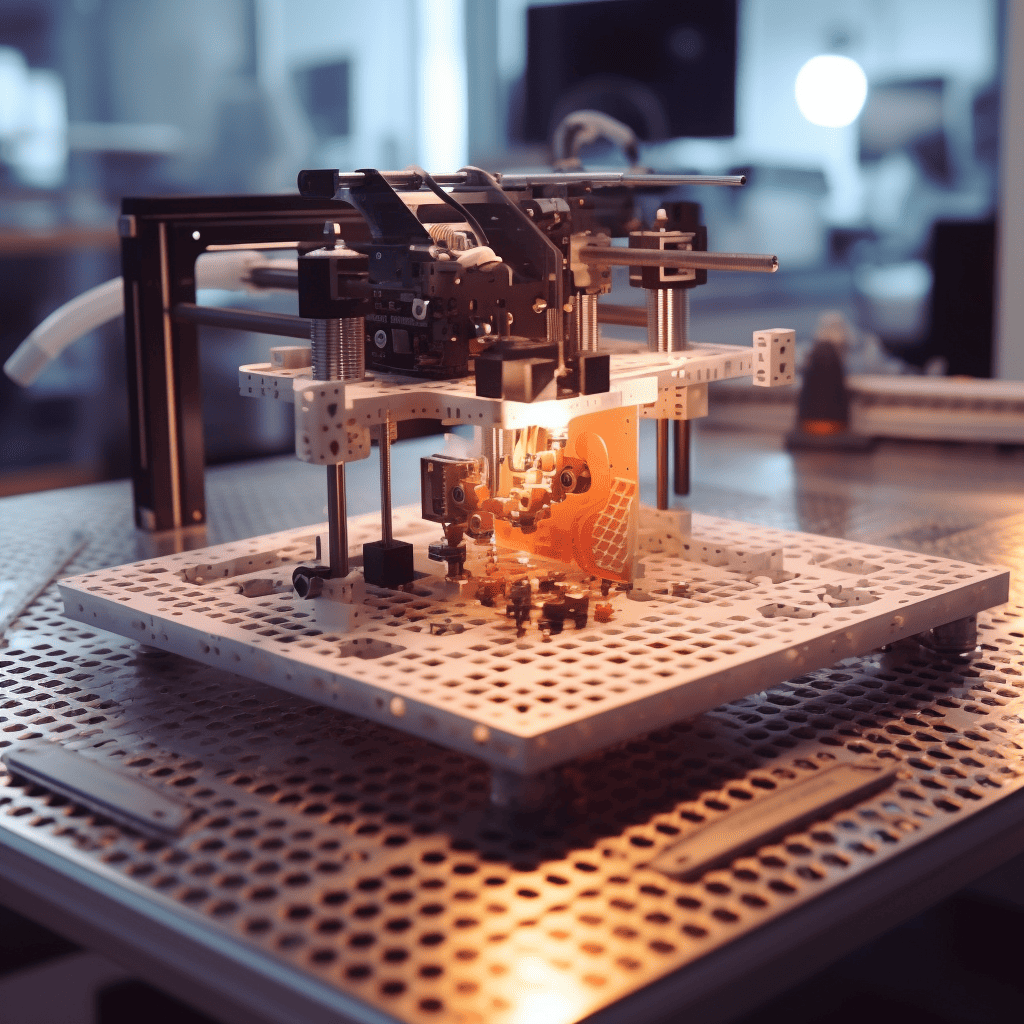

Developing disruptive technologies

- Moving from castings to additive process

- Reduce drilling / holes for using fasteners to using adhesives

- From zero / low robotics to large scale robotic assembly

- Creating intelligent flexible workstations with AI

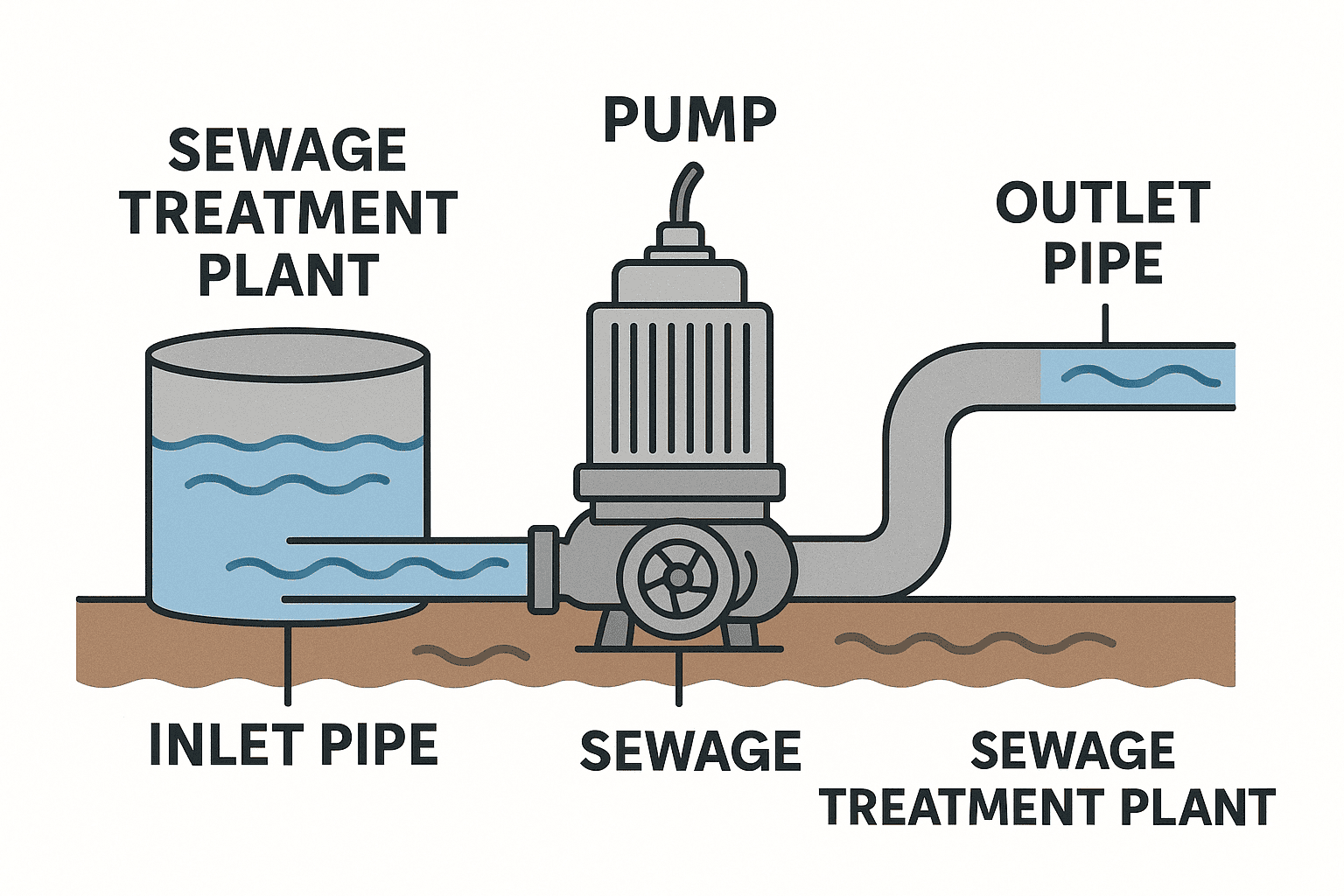

The Supply Chain Challenge

- Cloud based storage

- Digital Asset Tracking

- Digital Trust

- Reduced time to market

- Predictive analysis

- New regulations

The 9 components of Industry 4.0

The foundations of Supply Chain 4.0 ( Some say that the points below are all aligning.

- System integration

- Big data and analysis

- Simulation and virtualisation

- Internet of things (IOT)

- The cloud

- Cybersecurity

- Autonomous systems

- Augmented reality

- Additive manufacturing

Volatility – The need for change

The world is becoming more volatile

If we look at surviving a VUCA World – Volatility , Uncertainty, Complexity, Ambiguity and look at the volatility index plotted from 1970 to current Source: Datastream E14 (for crude oil data) Chicago Board Options Exchange

We can see that the world is becoming more volatile and the approaches / stuff we did in the 80’s , 90, 2000,s is no longer relevant.

The challenge

- Not enough people can walk the shop floor and identify where “disruptive” approaches could provide benefits.

- Like marketing supply chain is not seen as a skilled discipline

- Like marketing supply chain needs to be in the boardroom

- Owners / managers need to understand that leadership is critical Collaborative / shared leadership depends on real experience

- Cost to serve is a crucial skill that shouldn’t be left to the accountants

- We haven’t invested in capital equipment (just used more people) and this will ultimately cause issues in Food Production sector where with labour shortages we need more automation

If you would like a copy of the VUCA chart then contact Andrew Goode an experienced marketing and sales professional or for more information on business development approaches click here

The 4th Industrial Revolution and its impact on your business

Quick recap on the various industrial development stages. In the 1700’s the advent of steam to power machines and provide consistent repeatability of movement was transformational from the previous “manpower”. With Electricity being on tap in the 1800’s this provided all the advantages of lighting and powering. Bring on the 1900’s and computing comes on board to allow programming and increased control.

Note at each of these stages of massive disruption there were manufacturing companies that were winners and losers. Slide rule manufacturers, Fax machines, the steam train etc etc. The change from telephone to smartphone has enabled unprecedented change.

So with Industry 4 in the 2000’s with unprecedented change through the convergence of the physical, digital and biological worlds – how will your manufacturing business survive and thrive?

How does industry 4.0 fit in for your business? What is industry 4.0 for your business?

Lets consider how it worked for a Cambridgeshire based engineering manufacturing company Huxley Bertram

- using sensors / actuators allowed them to collect large amounts of data from equipment

- Within the design office ( in fact all office environments) using Evernote and Harvest

- Using Team Viewer and Google workspace

- HoloLens – mixed augmented reality product proved perfect where remote site working required and to overcome some of the issues created by Covid

Steps faced in the business transformation

- Levels of change – staff / team / organisation

- 6 M tools – manpower, methods, machinery, money , measurement

- Iterations – make, show, measure & learn

- People adoption types – work with the innovators and early adopters within the business. Those who are laggards wont thank you for asking them to change their ways

- You need a project sponsor to make change happen

Challenges For Manufacturers – The 8 step model for creating a climate for change

- 1: Create urgency

- 2: Form a powerful coalition

- 3: Create a vision for change

- 4: Communicate the vision

- 5: Empower action

- 6: Create quick wins

- 7: Build on changes

- 8: Make it stick

- 7: Build on changes

- 6: Create quick wins

- 5: Empower action

- 4: Communicate the vision

- 3: Create a vision for change

- 2: Form a powerful coalition

So as you can see there are essentially 3 major stages to overcome Challenges For Manufacturers. Points 1 to 3 are all about creating a climate for change. From 4 to 6 we are about engaging and enabling the organisation. Points 7 & 8 are all about implementation

Overcoming Challenges For Manufacturers

- Simplify / Standardise and Automate

- Always use the Fastest, Safest and Lowest cost process to ensure Right First Time Quality

- Its all about Data

- Engineering standards Define the Product. Tools like Visual Factory communicates the optimal process

- Knowing the detail

- Knowing the process

- Doesn’t distract

- Allows you to focus on the road

- Essentially What you need to know, When you need to know it

FREE Website Performance Check

- Speed plays an important part in website performance how well does yours perform on desktop and mobile?

- Is your site mobile responsive if not how many customers are you losing?

- Is your site HTTPS?

- With GDPR in place is your site legally compliant?

- Find out about loads more website performance issues

Challenges For Manufacturers – Summary

Small and medium-sized enterprise (SME) manufacturers face several challenges as they aim to grow their businesses. Some of the main challenges for manufacturers include:

- Access to Capital: One of the significant hurdles for SME manufacturers is obtaining adequate capital for expansion. Limited financial resources and difficulties in securing loans or investments can impede their growth plans.

- Market Competition: SME manufacturers often have to compete with larger, well-established companies with greater resources and economies of scale. This competition can make it challenging for SMEs to capture market share and differentiate themselves.

- Technological Advancements: Keeping up with rapidly evolving technologies can be a significant challenge for SME manufacturers. Adopting new manufacturing processes, machinery, and digital tools requires substantial investments and expertise, which may be difficult for SMEs with limited resources.

- Skilled Workforce: Finding and retaining skilled workers is a common challenge faced by SME manufacturers. Limited budgets for competitive salaries and benefits, as well as a shortage of skilled labour in some regions, can make it difficult to attract and retain talented employees.

- Supply Chain Management: SME manufacturers may face challenges in effectively managing their supply chains. Issues such as sourcing raw materials, inventory management, logistics, and maintaining relationships with suppliers can impact their production capabilities and overall efficiency.

- Regulatory Compliance: Compliance with various regulations and standards, such as safety, environmental, and labour laws, can be complex and time-consuming for SME manufacturers. Navigating these regulatory requirements adds administrative burdens and potential costs.

- Scaling Operations: As SME manufacturers grow, they often face difficulties in scaling their operations. Expanding production capacities, optimising processes, and managing increased complexity can strain resources and require careful planning.

- Innovation and Product Development: Developing innovative products and keeping pace with changing customer demands is crucial for growth. However, SME manufacturers may struggle with limited R&D budgets and a lack of specialised expertise in product development.

- International Expansion: Exploring international markets can offer growth opportunities, but it also presents challenges such as understanding foreign regulations, navigating cultural differences, establishing distribution networks, and managing global supply chains.

- Marketing and Sales: SME manufacturers often face challenges in effectively marketing and selling their products. Limited marketing budgets and a need to reach target customers through various channels can make it difficult to establish a strong brand presence and generate consistent sales.

Overcoming these challenges requires a combination of strategic planning, innovation, investment in technology and infrastructure, collaboration with partners, and a focus on operational efficiency. Government support, industry associations, and networking opportunities can also provide assistance to SME manufacturers in addressing these challenges.