Manufacturers Marketing

Marketing is a crucial function for manufacturers to promote their products and services to potential customers. In today’s competitive business environment, manufacturers must adopt effective marketing strategies to differentiate themselves from their competitors and capture a larger market share. This report provides an overview of the different approaches to marketing that manufacturers can adopt to promote their products and services.

1: Traditional Marketing Approaches

Traditional marketing approaches refer to the use of traditional media channels such as television, radio, print, and billboards to promote products and services. This approach is suitable for manufacturers that have a broad target audience and need to create brand awareness. Traditional marketing approaches have a wide reach and can help manufacturers reach a large audience quic

2: Digital Marketing Approaches

Digital marketing approaches refer to the use of digital channels such as social media, email, and search engine marketing to promote products and services. This approach is suitable for manufacturers that want to target a specific audience and create a personalized experience for their customers. Digital marketing approaches are cost-effective and provide measurable results, allowing manufacturers to track their return on investment.

3: Content Marketing Approaches

Content marketing approaches refer to the use of content such as blog posts, videos, and infographics to attract and engage potential customers. This approach is suitable for manufacturers that want to establish themselves as thought leaders in their industry and provide valuable information to their customers. Content marketing approaches are effective in building trust with potential customers and can lead to increased sales and customer loyalty.

4: Influencer Marketing Approaches

Influencer marketing approaches refer to the use of influencers, who have a large following on social media, to promote products and services. This approach is suitable for manufacturers that want to reach a younger audience and create a buzz around their products. Influencer marketing approaches are effective in creating brand awareness and can lead to increased sales and customer loyalty.

Lets consider these 4 elements in more detail

1: Traditional Manufacturing Marketing

Traditional manufacturing company marketing approaches refer to the use of traditional media channels such as television, radio, print, and billboards to promote products and services. Here are some examples of traditional marketing approaches that manufacturers can use:

- Print advertising: This includes placing advertisements in newspapers, magazines, and trade publications that are targeted to the specific industry or audience.

- Direct mail: This involves sending promotional materials such as brochures, flyers, or catalogs directly to potential customers through mail.

- Trade shows: Manufacturers can exhibit their products and services at trade shows and industry conferences to reach a large audience of potential customers.

- Outdoor advertising: This includes placing advertisements on billboards, buses, or other outdoor locations where they can be seen by a large number of people.

- Television and radio commercials: This involves creating a 30-second or 60-second advertisement to be aired on television or radio to reach a broad audience.

- Public relations: Manufacturers can use press releases and media coverage to generate publicity for their products and services.

These traditional marketing approaches can be effective for manufacturers that have a broad target audience and need to create brand awareness quickly. However, they can be expensive, and the results may not always be measurable. As a result, manufacturers are increasingly adopting digital marketing approaches to complement their traditional marketing efforts.

2: Digital Manufacturing Marketing

Digital manufacturing company marketing approaches refer to the use of digital channels such as social media, email, and search engine marketing to promote products and services. Here are some examples of digital marketing approaches that manufacturers can use:

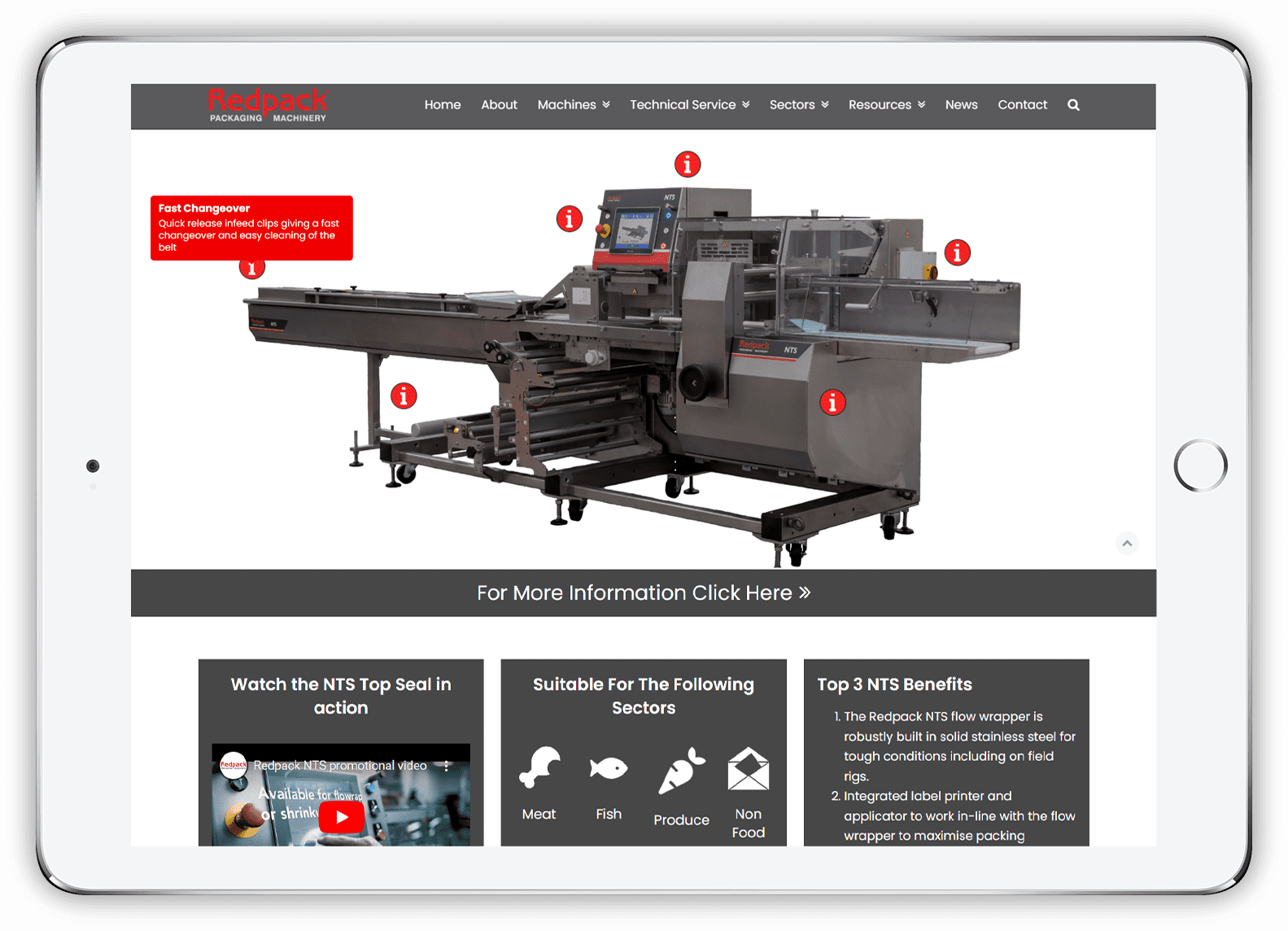

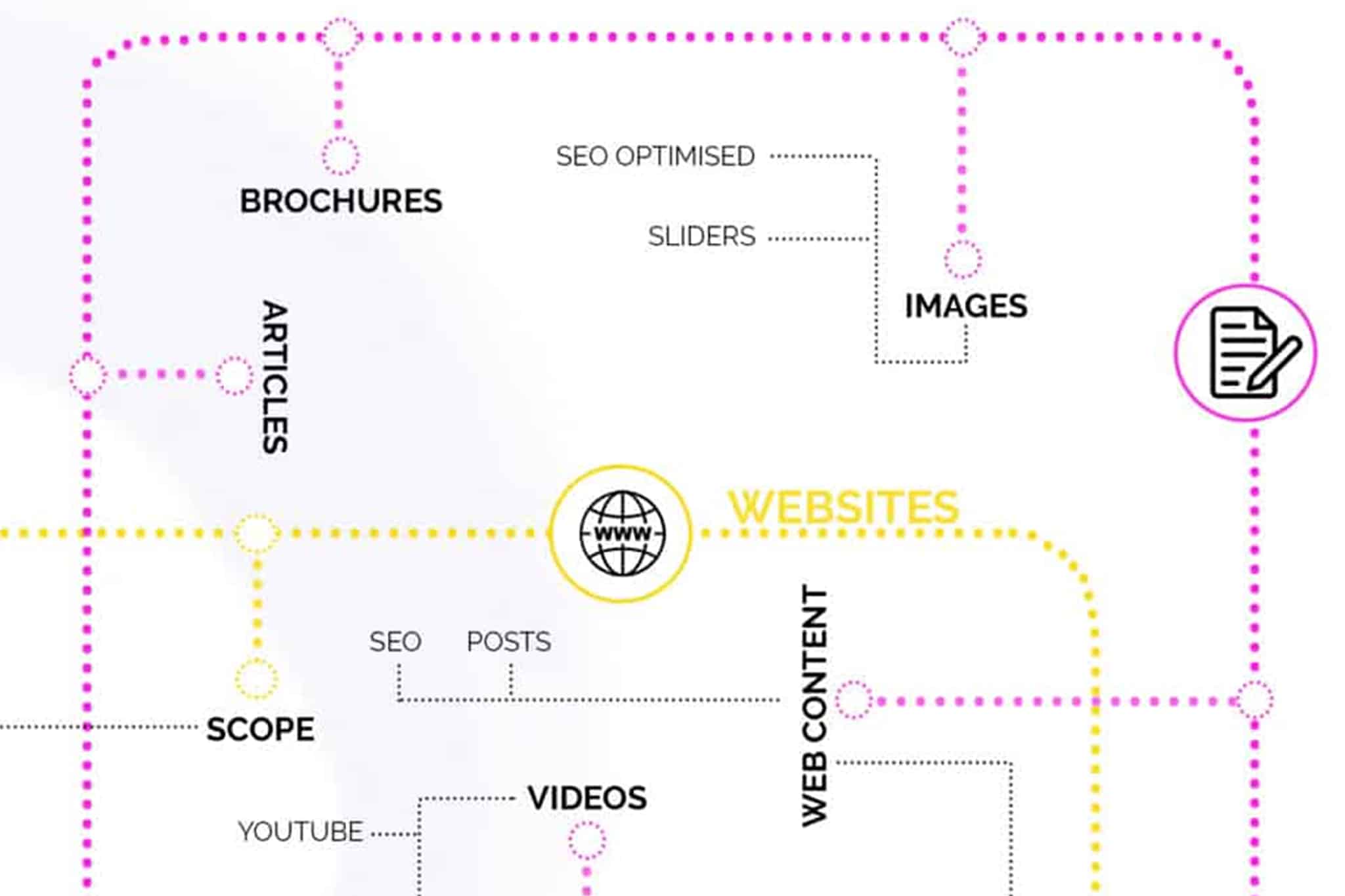

- Websites – Manufacturers need to have more than just a brochure website. Getting your website found and then converting any visitors are now fundamental business options for manufacturers

- Social media marketing: Manufacturers can use social media platforms such as Facebook, Twitter, and LinkedIn to promote their products and services, engage with customers, and build brand awareness.

- Email marketing: This involves sending promotional emails to customers and potential customers to promote products and services, share news, and provide updates.

- Search engine optimisation (SEO): Manufacturers can optimize their website and content to improve their search engine ranking, making it easier for potential customers to find them online.

- Pay-per-click (PPC) advertising: This involves placing paid advertisements on search engines and social media platforms to reach a specific audience.

- Content marketing: Manufacturers can create valuable content such as blog posts, videos, and infographics to attract and engage potential customers.

- Mobile marketing: This includes using mobile devices and apps to reach potential customers through targeted ads, push notifications, and SMS messages.

Digital marketing approaches are cost-effective and provide measurable results, allowing manufacturers to track their return on investment. They also allow manufacturers to target a specific audience and create a personalised experience for their customers. As a result, many manufacturers are shifting their marketing efforts towards digital channels to complement their traditional marketing approaches.

3: Content Marketing Manufacturing Marketing

Content marketing manufacturing company marketing approaches refer to the use of content such as blog posts, videos, and infographics to attract and engage potential customers. Here are some examples of content marketing approaches that manufacturers can use:

- Blogging: Manufacturers can create a blog on their website to share valuable information, insights, and updates about their products, industry, and trends. This can help to establish the manufacturer as a thought leader in their field and provide value to potential customers.

- Video marketing: Manufacturers can create videos to showcase their products, share customer testimonials, and provide educational content. This can be an effective way to engage potential customers and build trust.

- Infographics: Infographics can be used to present complex information in an easy-to-understand format. Manufacturers can create infographics to explain their products, processes, and industry trends.

- Case studies: Manufacturers can create case studies to showcase how their products have helped their customers solve specific problems or achieve specific goals. This can help to build credibility and demonstrate the value of their products.

- White papers: Manufacturers can create in-depth reports or white papers to provide valuable insights and research on their products, industry, or market. This can help to establish the manufacturer as an expert in their field and attract potential customers.

Content marketing approaches are effective in building trust with potential customers and can lead to increased sales and customer loyalty. They can also help to establish the manufacturer as a thought leader in their field and differentiate them from their competitors. As a result, many manufacturers are incorporating content marketing into their overall marketing strategy.

4: Influencer Manufacturing Marketing

Influencer marketing manufacturing company marketing approaches refer to the use of individuals with a significant social media following to promote products and services. Here are some examples of influencer marketing approaches that manufacturers can use:

- Social media influencers: Manufacturers can collaborate with social media influencers who have a significant following on platforms such as Instagram, YouTube, or TikTok to promote their products and services. Influencers can create sponsored posts, product reviews, or unboxing videos to promote the manufacturer’s products.

- Industry experts: Manufacturers can partner with industry experts such as bloggers, journalists, or podcast hosts who have a large following in their niche. These experts can provide valuable insights and recommendations about the manufacturer’s products and services.

- Brand ambassadors: Manufacturers can identify and work with brand ambassadors who have a strong connection with their products and can promote them to their network. These ambassadors can be employees, customers, or fans of the brand.

- Trade shows: Manufacturers can identify influencers or thought leaders who are attending trade shows or industry events and invite them to visit their booth. The manufacturer can then give them a personalized tour and showcase their products and services.

Influencer marketing can be effective in reaching a highly targeted audience and building brand awareness quickly. It can also provide social proof and validation of the manufacturer’s products and services. However, it’s essential to choose influencers who align with the manufacturer’s brand values and target audience to ensure a successful partnership.

Manufacturers Marketing

manufacturers need to change their marketing approaches to stay competitive in today’s digital landscape. Traditional marketing approaches such as trade shows and print advertising are still relevant but are no longer sufficient in reaching and engaging with potential customers. To succeed in the digital age, manufacturers must embrace digital marketing approaches such as social media, content marketing, and influencer marketing.

Digital marketing provides manufacturers with cost-effective and measurable ways to reach their target audience, build brand awareness, and generate leads. By creating valuable content, engaging with customers on social media, and collaborating with industry influencers, manufacturers can establish themselves as thought leaders in their industry and differentiate themselves from their competitors.

In addition to digital marketing, manufacturers must also focus on delivering an exceptional customer experience by providing high-quality products, personalized service, and timely support. By leveraging both digital marketing and exceptional customer service, manufacturers can build a loyal customer base and drive long-term success.

In summary, the manufacturing industry is evolving rapidly, and manufacturers must adapt their marketing approaches to keep pace with changing consumer behaviour and expectations. By embracing digital marketing and delivering an exceptional customer experience, manufacturers can thrive in today’s competitive landscape.

If you would like to know more about manufacturers marketing metrics and analysis contact Andrew Goode MBA, MSc, FCIM Click here to arrange a call

Other articles linked with marketing metrics that may provide additional insight. Marketing metrics and analytics, marketing ROI Planning , marketing revenue analytics and Marketing Measurement Metrics